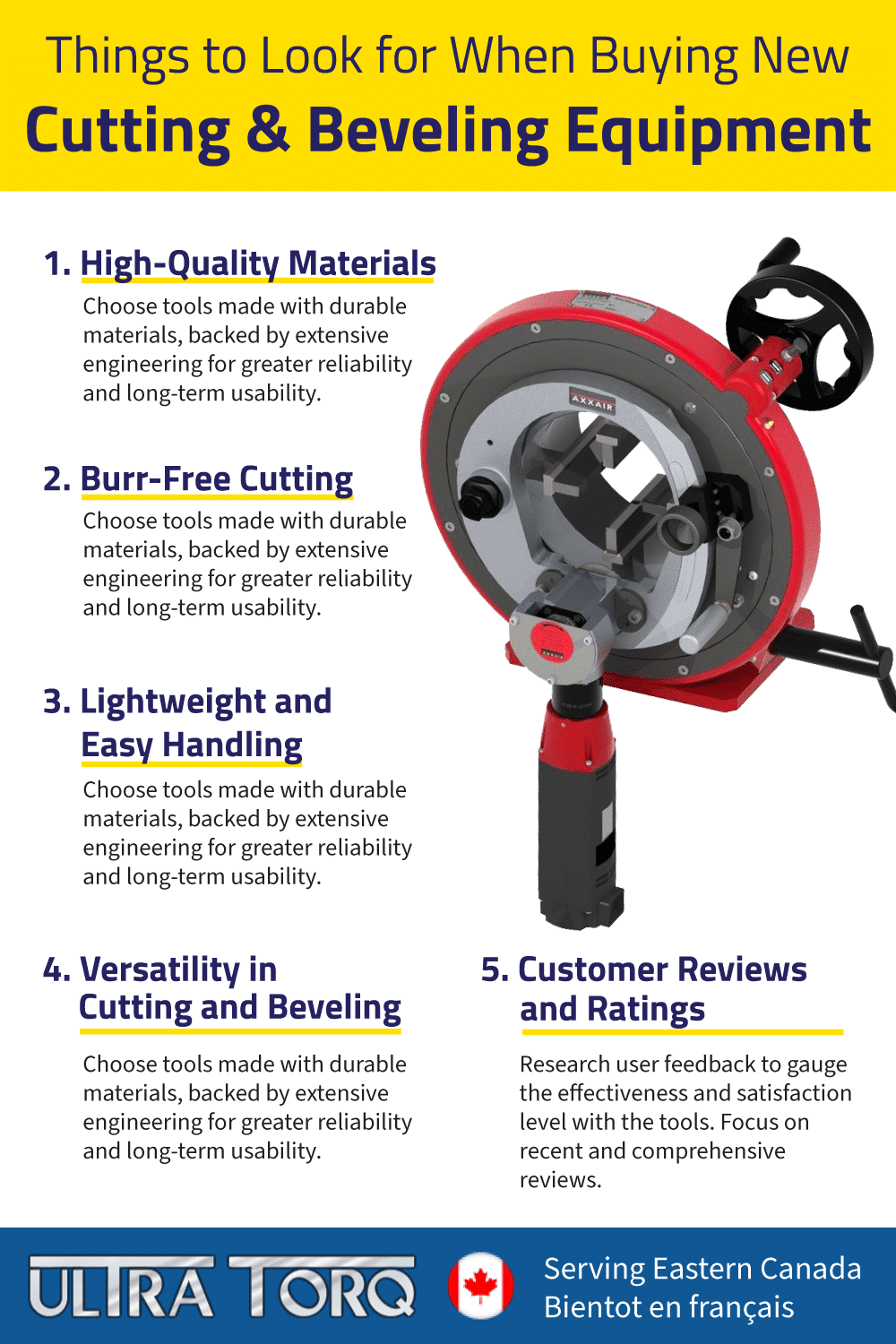

When it comes to orbital cutting and beveling tools, there is a broad spectrum of brands and products to choose from. If you need more features, better strength, top quality, and greater breadth of selection, consider the tools available at Ultra Torq.

1. High Quality Materials

Companies that sell high-quality tools strive to make their tools better, instead of focusing solely on profits. At Ultra Torq, our high-quality orbital cutting and beveling tools have the following properties:

- Are made of the best, appropriate and durable materials

- Are built through an investment in engineering, research and development time

- Designed with intention and user experience in mind

- Have a history of skilled craftsmanship, excellence and reliability

Our suppliers are standing for this aim with their expertise and experience.

2. Burr-free Cutting Abilities

Our orbital cutting tools incorporate the design of conceptually flexible light tube saws for burr-free cutting of tubes and elbows. The most important advantages of attaining burr-free cutting include:

- Producing high-quality finishes

- Safer material handling and increased personal safety

- Better adhering paint

- Reduced liability

Our orbital cutting and beveling tools reduce potential liability considerably by completely removing burrs from part surfaces as well as interior and exterior edges. In essence, they help produce parts that are safe, aesthetically pleasing, and ready for smooth processing downstream.

3. Lightweight and Easy Handling

Lightweight orbital cutting and beveling tools are easy to handle. While designs remain rugged for a long product life, using tools that are lightweight and easy to handle produce less stress and fatigue on users.

Without the extra bulk, users will experience less muscle fatigue and have better control over the operation of the tool, even after a long day. The benefits of an ergonomically focused design include better grip and pivot during use, and the size makes it easier to complete a range of specific applications.

4. Adjustable, Simultaneous or Separate Cutting and Beveling Options

Adjustable, simultaneous or separate cutting and beveling options can help with minimizing material wastage. This results in safe preparation of pipe ends for welding to ensure consistency and quality.

At Ultra Torq, we strive to achieve your economic goals and improve the productivity and accuracy of your machining projects. With over 130-man years in bolting experience, we have proven that we do not simply provide tools and equipment, we provide concrete solutions.

5. Consider Reviews

Searching for customer reviews can help you determine which orbital cutting and beveling tools are reliable, have the highest quality, and deliver satisfaction to other users. When reading reviews, it’s important to consider:

- Average star rating

- Total number of reviews

- Review frequency and age

- The sentiment of the reviews

By evaluating reviews from websites, stores, and other industry professionals, you can make a better decision on which product is right for you.

Getting Your Orbital Cutting and Beveling Equipment from Ultra Torq

Our goal is to supply our customers across Eastern Canada with cost-saving orbital systems solutions. Whether you’re cutting tubes or pipes, we carry the largest and most comprehensive supply of the latest orbital cutting and beveling tools. No matter what you require for bolt tightening, Ultra Torq has you covered. Contact us today.