The Leader in Industrial Pipe & Bolting Tools

Since 2002

Ultra Torq is Eastern Canada’s major supplier of high-quality portable Tools for tube and pipe contractors.

With over 130-man years in bolting experience, we have proven that we do not simply provide tools and equipment, we provide concrete solutions. Our bolting and torquing products are used throughout Canada in various industrial environments. No matter what you require for bolt tightening, Ultra Torq has you covered.

We are excited to announce that Ultra Torq Bolting Tools has recently been certified by ANAB as an ISO/IEC 17025:2017 Accredited Calibration Laboratory

Learn MoreHigh Tech Tightening Solutions From Canada’s

Trusted Torquing Supplier

Ultra Torq has been providing Canada and Eastern Canada with reliable and innovative equipment needed to run industries effectively and efficiently – and we just got even better.

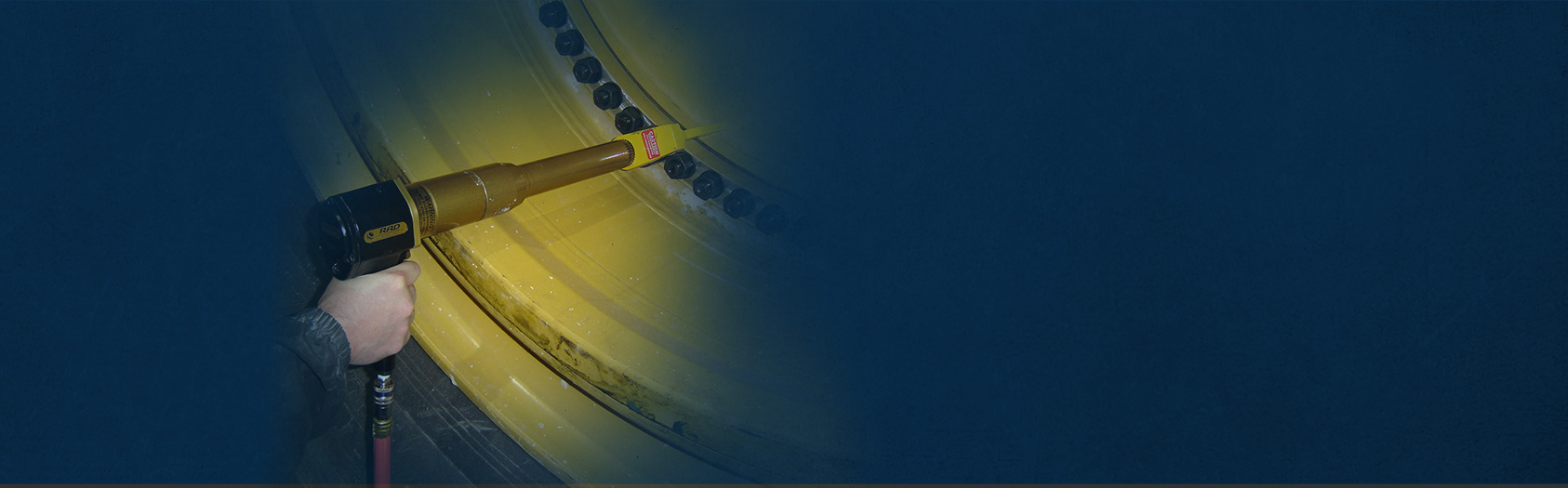

We are proud to be the first to distribute Torq-Comm’s Commander XT product line of advanced Bluetooth-enabled technology that calculates proper torque, provides instructions to operators, and records data. Our line of advanced tightening solutions for quality control and production are here to change the way you operate.

Learn more about these high-tech solutions below:

Why You Should Choose Torq-Comm’s Commander XT Products

These highly advanced torque recording solutions were designed to allow managers track the bolting process and to store this real time data as an insurance of proper work process in case of future equipment failure.

- Designed to record data points in real time, so you never miss an aspect of a torquing project.

- Combines precision reporting with wireless pump pressure control adjustment, for a seamless and error-free operation.

We’re Here To Make Your Torque & Bolting Decisions Easier

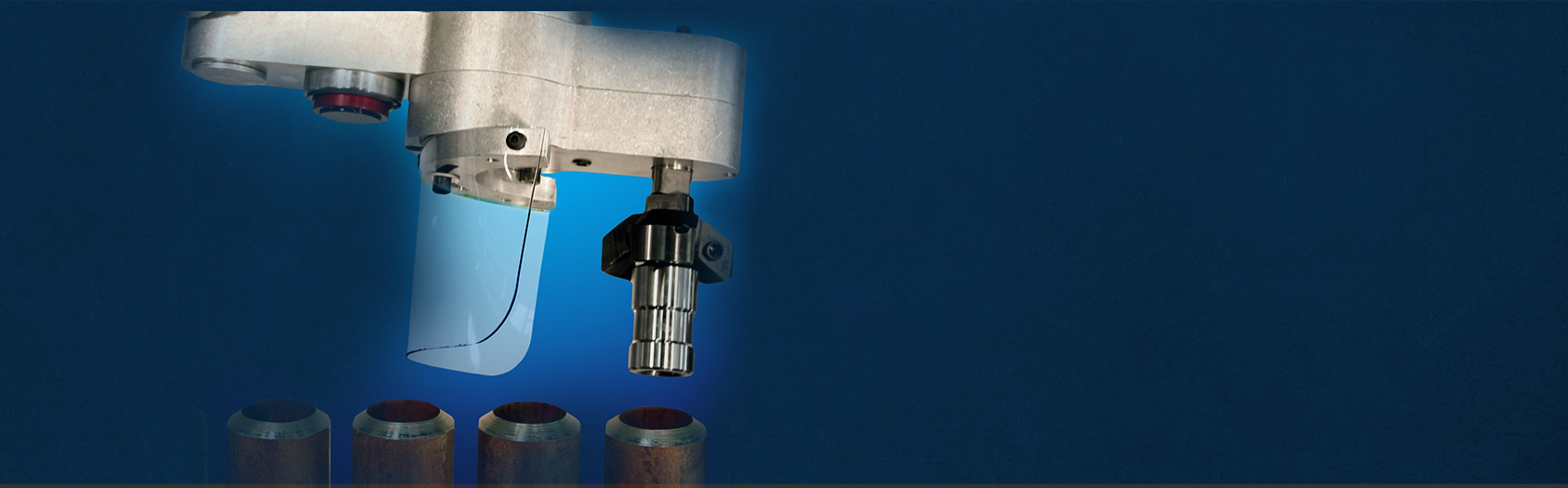

You are constantly trying to make your operations run more smoothly, and we are constantly trying to come up with ways to help you do that.

Ultra Torq industrial torque & bolting Tools in Canada has a long history of breaking the mold, and we stick to our promise of providing the best torque and tension tools that you will ever own.

If you can't recall the data, it's time to get to it.

WORKER TRAINING GUIDE Get Your Copy